Storage tanks are essential equipment in the oil, gas, petrochemical, and chemical industries. Among the many tank types, floating roof tanks hold a special position for the storage of volatile liquids and hydrocarbons due to their unique properties. These tanks are designed so that their roof remains above the liquid surface and rises and falls depending on changes in water level. This significantly reduces evaporation, product loss, and environmental damage.

In this article, we provide a comprehensive overview of floating roof tanks, including their types, components, applications, advantages, and key points regarding design and maintenance.

History and necessity of floating roof tanks

With the development of the oil industry and the increasing storage of volatile products such as gasoline, crude oil, and light oil, problems with evaporation, air pollution, and the risk of explosion also increased. To solve these problems, engineers developed tanks with roofs that touched the liquid surface, thus reducing vapor space. This innovation led to the development of floating-roof tanks, which are widely used in refineries, oil refineries, and petrochemical plants.

General design of a floating roof tank .

Floating roof tanks typically consist of the following parts:

-

Body: The main part of the tank, which has a cylindrical shape.

-

Tank bottom: a steel plate that serves as the base and support for the entire structure.

-

Floating roof: A movable plate placed on the liquid surface that moves with the liquid level.

-

Sealing: A device that prevents the penetration of vapor between walls and ceilings.

-

Accessories: Includes ladders, steering arms, rainwater drainage systems, fans, and safety equipment.

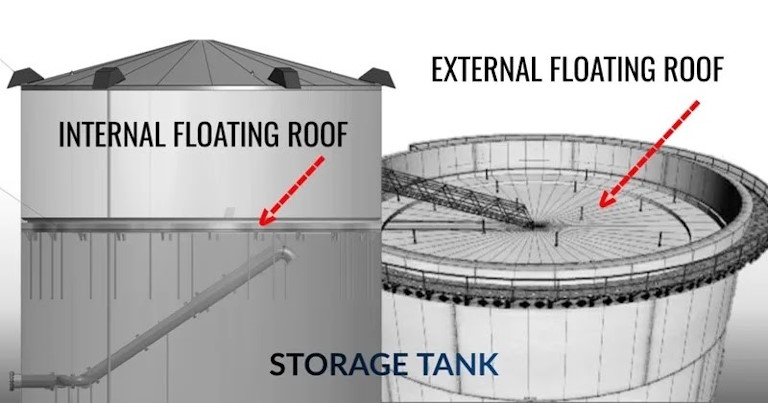

Types of floating roof tanks

There are two main types of floating roof tanks:

1. External Floating Roof Tank (EFRT)

This type of roof is directly exposed to wind and rain and requires special equipment to collect and protect rainwater. This equipment is primarily used for storing light petroleum products such as gasoline and ligroin.

2. Indoor floating roof tank (IFRT)

In this model, the floating roof is located inside the tank, with a fixed roof above it. This combination increases safety, reduces weather exposure, and improves insulation. A floating roof inside the tank is recommended for storing sensitive chemicals or valuable fuels.

The main components of a floating roof

-

Main deck: can be single-layer, double-layer, or made of aluminum and steel.

-

Sealing system: Includes primary and secondary seals to prevent evaporation and vapor leaks.

-

Roof ladders/walkways: Allow the operator to access different parts of the roof.

-

Rainwater drainage system: Flexible pipes or hoses for draining water from the roof.

-

Floating or sliding rods: Stabilize the roof and prevent excessive movement due to wind or liquid flow.

Advantages of floating roof tanks

-

Reduced evaporation: Because the roof is in direct contact with the liquid surface, the evaporation rate of the product is significantly reduced.

-

Cost savings: Avoid waste of volatile products and reduce costs.

-

Increased safety: By reducing the vapor space above the liquid, the risk of explosion and fire is reduced.

-

Environmental protection: Reduction of hydrocarbon vapor emissions into the air and thus reduction of environmental pollution.

-

Flexibility: Suitable for all types of petroleum-based liquids and chemicals.

Disadvantages and limitations

While tanks with floating roofs offer many advantages, they also have limitations:

-

Compared to tanks with a fixed roof, construction and maintenance costs are higher.

-

Gates and drainage systems require regular maintenance.

-

Exposed to heavy rain or wind (especially outdoors).

-

It is not effective on liquids with high boiling points or materials that evaporate slowly.

Applications of floating roof tanks

-

Storage of crude oil in export terminals and refineries .

-

Storage of gasoline, naphtha, diesel fuel and other light petroleum products.

-

Used in the chemical industry for the storage of solvents and volatile substances .

-

Storage of liquids requiring careful evaporation control and protection from environmental contamination .

Design methods and standards

The design and construction of floating roof tanks must comply with international standards. The most important of these are:

-

API 650 : Standard for the design and construction of steel storage tanks.

-

API 653 : For inspection, maintenance and repair.

-

API 2000 : For tank ventilation and safety.

Important points to consider when designing:

-

Choose the right material for the floor, body and roof (steel or aluminum).

-

The precise design of the sealing system reduces steam emissions.

-

Provision of suitable rainwater drainage systems.

-

Wind, earthquake and snow loads must be taken into account in the calculation.

Maintenance and inspection of floating roof tanks

To ensure proper operation and extend the service life of the tank, regular checks must be carried out:

-

Visual inspection: Check the condition of the seal, body and tank bottom.

-

Non-destructive testing (NDT): detection of cracks or corrosion.

-

Leak test: Make sure the floating roof is completely sealed.

-

Repair and replace worn parts, especially drain pipes and hoses.

The future of floating roof tanks

Due to the global trend toward reducing pollutant emissions and improving energy efficiency, floating storage tanks are becoming increasingly popular. New developments in waterway design, the use of lightweight, corrosion-resistant alloys, and the implementation of intelligent monitoring systems make floating storage tanks an ideal choice for the oil and chemical industries.

Finally

Floating roof tanks are among the most efficient and safe methods for storing volatile liquids. They play an important role in the petroleum and petrochemical industries, reducing evaporation, maintaining product quality, lowering costs, and limiting environmental pollution. However, they also present numerous challenges, such as high construction and maintenance costs , the need for regular inspections, and operational limitations. Nevertheless, their significant advantages make them an ideal choice for fuel and chemical storage.