Caustic soda (sodium hydroxide – NaOH) is one of the most widely used chemicals in industries such as paper, detergent, textiles, water treatment and petrochemicals. Due to its high alkalinity and reactivity, this substance requires special storage and transport conditions. Use of appropriate storage tanks for caustic soda is critical not only to preserve the quality of the material, but also to prevent threats to safety and the environment.

In this article, we will learn about the features, types, design requirements, and key points of maintenance and operation of these water tanks.

1. What is caustic soda and why is it important to store it?

Caustic soda is a strong base that exists in a liquid (varying concentrations) or solid state at room temperature. It has a strong corrosive effect on the skin and eyes and can produce dangerous amounts of heat and vapor when reacting with certain metals or acids.

Due to its corrosive properties, it is necessary to use containers that have sufficient chemical resistance to sodium hydroxide.

2. Characteristics of suitable storage tanks for caustic soda

For safe storage of this material , the tank must have the following properties:

-

High resistance to alkaline chemicals .

-

Does not react with materials even at high temperatures and high concentrations.

-

Sufficient mechanical strength to withstand the pressure and weight of the material.

-

Hermetic design with a reliable seal.

-

Determine the permissible operating temperature based on storage conditions and the process.

3. Caustic Soda Storage Tank Material

a) Polyethylene tanks (HDPE or XLPE)

-

Features: Excellent alkali resistance, light weight and easy installation.

-

Application: For storing caustic soda solution at room temperature and pressure.

-

Limitations: Careful study is required at temperatures above 50°C.

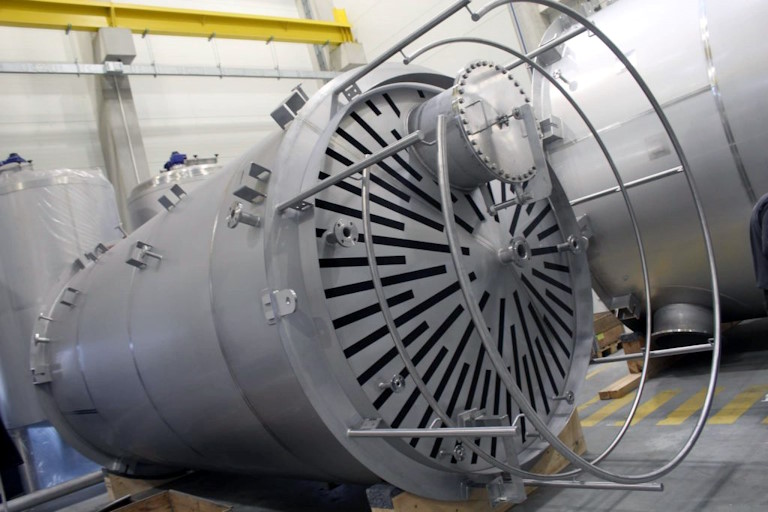

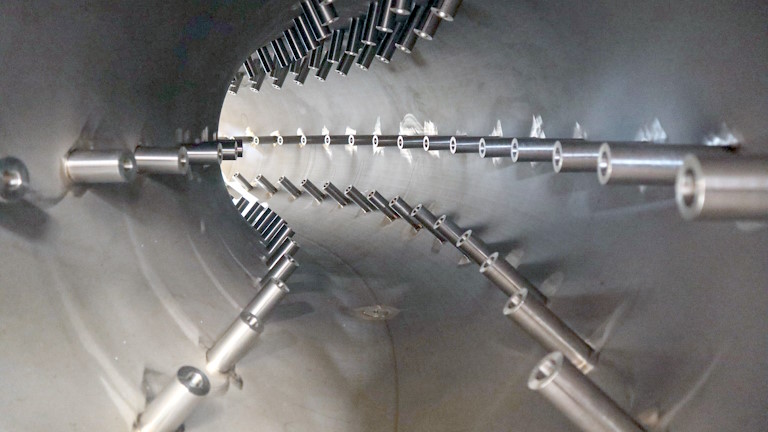

b) Stainless steel tanks (stainless steel – grade 316 or 304)

-

Advantages: High strength, long service life, can be used at higher pressures and temperatures.

-

Limitations: High price, may be corrosive under certain concentrations and conditions.

c) Fiberglass (FRP) tanks with appropriate lining.

-

Advantages: Excellent chemical resistance, large production volumes and long shelf life.

-

Application: Storage of large volumes of caustic soda in large industrial plants.

4. Key Points of Caustic Soda Tank Design

-

Tank shape: Usually designed vertical with a conical bottom to allow for complete drainage.

-

Ventilation system: prevents the accumulation of alkaline vapors and overpressure.

-

Corrosion-resistant connections: Valves and flanges should be made of alkali-resistant materials (e.g., PVC-U or special steel).

-

UV protection coating: If the tank is installed outdoors.

-

Thermal insulation: When storing the solution in cold or hot rooms.

5. Capacity and location of the facility

-

The capacity of the tank is determined based on the daily or monthly consumption and the amount of caustic soda required.

-

The installation site should have a flat, solid surface and be easily accessible for loading and unloading.

-

Keep a safe distance from other incompatible chemicals, such as acids , to avoid unwanted reactions.

6. Safety measures when using caustic soda tanks

-

Personal protective equipment: When loading and unloading, wear chemical-resistant gloves, goggles and a face mask.

-

Clean and inspect regularly: Check for leaks, cracks, and corrosion.

-

Clearly labeled: Containers should be clearly labeled with the name of the substance, the hazards and the safety instructions.

-

Avoid contact with water or acid: Sudden contact may result in violent reaction and splashing.

7. Periodic maintenance and inspection

-

Monthly Visual Inspection: Detects cracks, discoloration, or leaks.

-

Hydrostatic tests are carried out annually to confirm the strength of the structure.

-

Cleaning with a compatible solution: There is no need to use brushes or abrasive tools that can damage the inside.

EN 13445 Standard Pressure Vessels Without Fire Firing

EN 13445 Standard Pressure Vessels Without Fire Firing

8. Industrial uses of caustic soda and the importance of having appropriate storage tanks

Caustic soda is used in a wide variety of industries, including soaps and detergents

, oil refining, food processing, and aluminum. In all of these industries, the quality of the solution and the safety of employees are highly dependent on the correct selection and maintenance of containers financial and personal losses.

9. Conclusion

Selecting a storage tank for caustic soda is a complex and demanding process that requires consideration of the type of material used, its capacity, installation location and operating conditions. Following safety regulations, using personal protective equipment and conducting periodic inspections are essential to prevent accidents and maintain the quality of the material.

To ensure the purchase and installation of a safe and durable water tank, it is best to seek advice from a reputable technical expert and supplier.