Oxygen cylinders are essential equipment in medicine, industry, diving, and even firefighting. The oxygen in these cylinders is typically stored at high pressure (150 to 200 bar or more). Therefore, even the smallest crack or defect in the cylinder body can pose a serious hazard, including explosion, fire, death, and property damage. Hydrostatic testing is one of the most reliable methods for verifying the serviceability and safety of oxygen cylinders.

This article explains in detail the hydrostatic testing of oxygen cylinders, including its importance, steps, criteria and key points.

What is a hydrostatic pressure test?

Hydrostatic testing is a non-destructive testing method for assessing the strength and durability of high-pressure containers, such as gas cylinders. In this test, the container is filled with water instead of gas and subjected to pressures exceeding the operating pressure . Unlike gas, water is incompressible. Even in the event of a rupture, significantly less energy is released, reducing the risk of explosion.

Why is hydrostatic testing of oxygen cylinders necessary?

1. Personal and financial security : Prevent capsule explosions or leaks in sensitive environments such as hospitals and workshops.

2. Compliance with legal requirements and standards : National and international organizations (such as the Iranian National Standard, the Ministry of Transportation, the International Organization for Standardization, and the European Organization for Standardization) require regular testing.

3. Extend capsule life : Detect small cracks, rust, or defects before they lead to total failure.

4. Ensure equipment efficiency : Especially in critical situations where oxygen is urgently needed.

Time range for hydrostatic tests

According to the standard, oxygen cylinders must be checked at certain intervals:

-

First tests : after production and before market launch.

-

Periodic inspection : Normally every 3–5 years (depending on the relevant standard).

-

Special tests : When severe impacts, deformations or internal or external rust are detected.

Steps to check the water pressure in an oxygen cylinder

1. Initial examination

-

Inspect the outer surface of the capsule for rust, scratches, deformation, or surface cracks.

-

Control ports, valves and threads.

-

Make sure the capsule is not overfilled or overheated.

2. Empty the capsule completely.

-

The remaining gas must be safely released.

-

The capsules must be completely dry to avoid interactions with water or other substances.

3. Add water.

-

The cylinder is filled with clean water without impurities.

-

The presence of water instead of gas reduces the likelihood of explosion when pressure is applied.

4. Apply pressure.

-

The capsule is connected to the testing device.

-

The hydrostatic pressure is typically twice the cylinder’s working pressure. For example, if the working pressure is 150 bar, the test pressure is approximately 225 bar.

5. Measure the volume change

-

The device measures both permanent volume changes (permanent expansion) and temporary volume changes (elastic expansion) of the capsule.

-

If the continuous change in size exceeds the permissible limit, the capsule is rejected.

6. Drain and pat dry.

-

After testing, filter the water and dry the capsule completely to prevent internal oxidation.

7. Record and document the results.

-

If the test is passed, the test date and technical data are engraved into the capsule body.

-

If a defect occurs, the capsule must be removed from the consumer cycle.

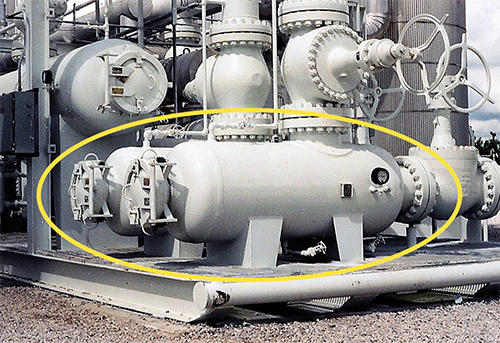

NASA Standards for Bottom Pressure Vessels and Pressure-Maintaining Systems (PVS)

Standards for hydrostatic tests

There are several internationally recognized standards for testing compressed capsules:

-

ISO 6406 : Periodic inspection and testing of gas cylinders.

-

EN 1968: Testing and inspection of seamless steel cylinders.

-

Department of Transportation (DOT) : US regulations for the transport and storage of gas cylinders.

-

Iranian National Standards (ISIRI) : Standards and test methods for compressed gas cylinders.

The difference between hydrostatic testing and air pressure testing

-

Hydrostatic pressure test : Performed with water, is safer and carries a very low risk of explosion.

-

Pneumatic : Uses air or an inert gas (such as nitrogen). However, because gas is compressible, it is relatively hazardous and is usually used under special conditions.

Important points of the water pressure test in an oxygen cylinder

-

The test must be performed by an accredited center that has received standard approval.

-

The use of precise equipment and calibration is crucial.

-

Capsules that fail the test cannot be refilled or used.

-

After each test, the results must be recorded in an instrument log or data recording system.

-

After testing, the capsules should be thoroughly dried and stored under appropriate conditions.

The costs for testing an oxygen cylinder under water pressure

The cost of this test depends on the capsule size (2, 5, 10, or 40 liters), the material type (steel or aluminum), and the service center. However, compared to the risk of capsule explosion or other damage, these costs are minimal.

Finally

Due to the high pressure in oxygen cylinders, regular inspections and testing are required. Hydrostatic testing is a reliable and standardized method to ensure the safety, durability, and performance of these devices. These tests are not only required by law but also a necessary measure to protect human life and prevent economic losses.

If you use oxygen cylinders in medical, industrial, or residential applications, remember that regular inspections and hydrostatic pressure tests are critical to their safety and proper operation.